Xinyuan Fashion

- 25 years garment production experience

- 20 years export experience

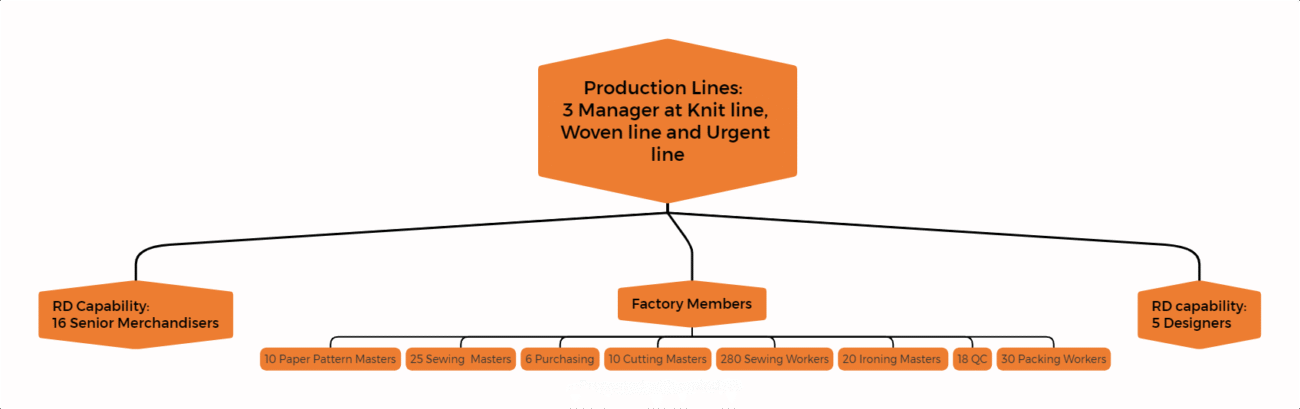

Xinyuan has strong production capabilities to ensure that your orders are delivered on time. Our factory is equipped with advanced machinery and has a skilled and experienced production team to ensure product quality. We pride ourselves on our efficient and professional production processes, which enable us to provide customers with high-quality customized fashion apparel of women's wear and men's wear, muslim fashion at competitive prices.

Hot press is commonly used to create prints and graphics on garments and textiles such as t-shirts, tank top,shorts, etc.

Digital printing machines utilize inkjet or dye-jet technology to precisely apply patterns onto fabric, guided by computer-controlled movements of the print head and ink jets. This method allows for high-quality, high-resolution prints with enhanced design flexibility.

The semi-automatic screen printing machine is to manually operate the squeegee to scrape the ink paste evenly across the screen template, so that the ink paste penetrates the screen and prints patterns and designs. Semi-automatic screen printing machines are suitable for small batch production and custom printing needs.

The embroidery machine can perform embroidery operations automatically, and embroider according to pre-designed patterns and programs, and can realize complex patterns and multi-color embroidery.

Electric cutting machine is a device that uses electricity to cut fabrics and textiles. It usually has an automated cutting function that can quickly and accurately cut out the desired fabric shape. This equipment improves the speed and accuracy of cutting. sex, saving time and labor costs.

The laser cutting machine uses the high energy density of the laser beam to cut fabrics without traditional knives. The laser cutting machine has very high precision and flexibility, and can realize complex cutting and embroidery patterns. It is suitable for all types of fabrics and reduces cutting errors and fabric waste.

The purpose of the automatic button feeder is to fasten and efficiently button garments. For mass production, the automatic button feeder can greatly improve production efficiency, reduce labor costs, and ensure the consistency and accuracy of button sewing. This can help us complete orders faster, meet customer needs, and improve factory production capacity and competitiveness.

Metal Needle Detector can help to find and remove metal impurities in time, such as needles, needle tubes, needle pieces, buttons, etc., improve product quality and safety, and ensure that products meet the requirements of regulations and standards.

Our design team boasts extensive experience and professional expertise, offering a wide range of pattern design services in various styles. Utilizing the latest design software and tools, we swiftly create unique and personalized patterns. Our designers blend digital software with hand-drawing techniques to craft patterns, which are then converted into detailed technical drawings for the production process. We carefully consider factors like complexity, size, and fabric to ensure the final clothing pattern meets your expectations and is optimized for successful production.

Our modeling team combines advanced technology with extensive experience to quickly and accurately create realistic, detailed samples. We use 3D modeling software to deliver the most lifelike representations, helping you gain a clear understanding of your design. Our three-dimensional solid models showcase the appearance, details, and structure of the clothing, enabling you to assess and evaluate design solutions more effectively. Using CAD software, we create 3D models that can be adjusted and refined to meet your specifications. This modeling process helps us identify potential issues early, saving both time and costs in actual production, while also enabling faster sample preparation and mass production.

With factories located in Guangdong and Hubei, we offer a wide range of processes and fabrics, seamlessly integrating the entire supply chain. Our two business units in South China and Central China stay up-to-date with the latest trends in the Chinese clothing industry, frequently participating in both domestic and international exhibitions. We also keep a close eye on fashion magazines like Harper’s Bazaar for relevant product insights. Once you provide the product details, we can swiftly identify the required fabrics and processes, offering immediate solutions for production samples.

Our design team includes professionals from prestigious institutions like the Wuhan Academy of Fine Arts, Wuhan Textile University, and the Guangdong Design Institute, all bringing exceptional academic and aesthetic expertise. We also collaborate with overseas part-time designers to strengthen our R&D and design capabilities. If you’re a designer passionate about global fashion brands, we invite you to join us and collaborate. Our partnerships with renowned third-party design companies like ASOS, PALACE SKATEBOARDS, and ZANEROBE ensure we work with top-tier talent, continuously enhancing our R&D and innovation. By leveraging resources in fabrics, accessories, technology, talent, information, and market expansion, we stay ahead of global apparel trends and look forward to working with you.

Factory certification is a cornerstone of XINYUAN Apparel’s commitment to quality management and regulatory compliance. Our certified manufacturing processes build strong customer trust and enhance our competitive advantage in the global apparel market. Beyond compliance, factory certification drives continuous improvement, supporting our operational excellence and contributing directly to our company’s long-term success. Additionally, these certifications lay a robust foundation for sustainable development by aligning with environmental and social responsibility standards.

Choosing a certified factory like XINYUAN guarantees reliable quality control, compliance with international standards, and a partner dedicated to innovation and sustainability.

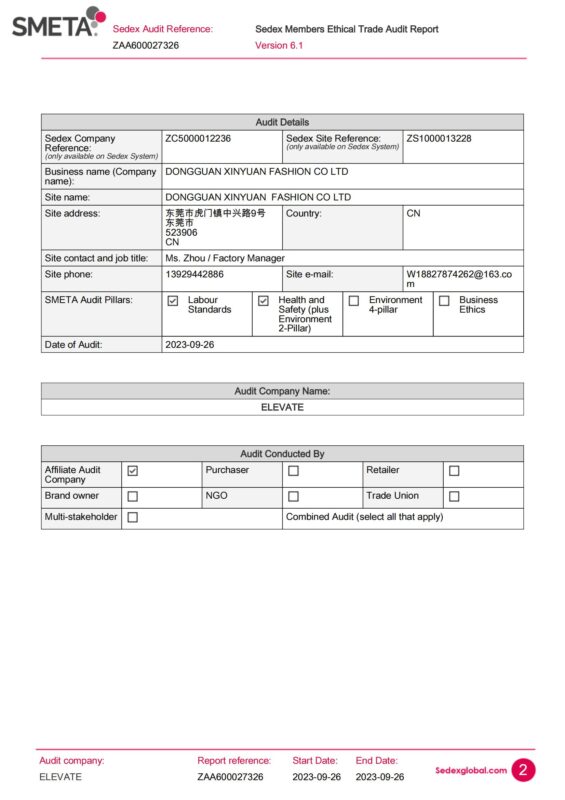

Sedex Certification – Commitment to Ethical and Sustainable Supply Chain

At XINYUAN Apparel, we proudly hold the Sedex certification, demonstrating our dedication to ethical business practices, social responsibility, and environmental sustainability throughout our supply chain. As a verified member of the Supplier Ethical Data Exchange (Sedex) platform, we ensure compliance with global standards on labor rights, health and safety, and environmental protection.

Our Sedex-certified factory guarantees transparency and accountability, providing global buyers with confidence in responsible sourcing and sustainable garment manufacturing. Choosing a Sedex-certified partner like XINYUAN helps your brand meet growing demands for corporate social responsibility (CSR) and ethical supply chain management.

At XINYUAN Apparel, we offer comprehensive textile testing services essential for global apparel brands to ensure fabric quality and regulatory compliance. Our capabilities include accurate fiber composition analysis, colorfastness testing (wash, rubbing, light, perspiration), shrinkage evaluation, tensile strength and tear resistance measurement, pilling resistance assessment, and chemical residue testing to meet international standards. With fast turnaround times and detailed reports, our professional fabric testing helps you maintain high-quality garments and minimize supply chain risks.

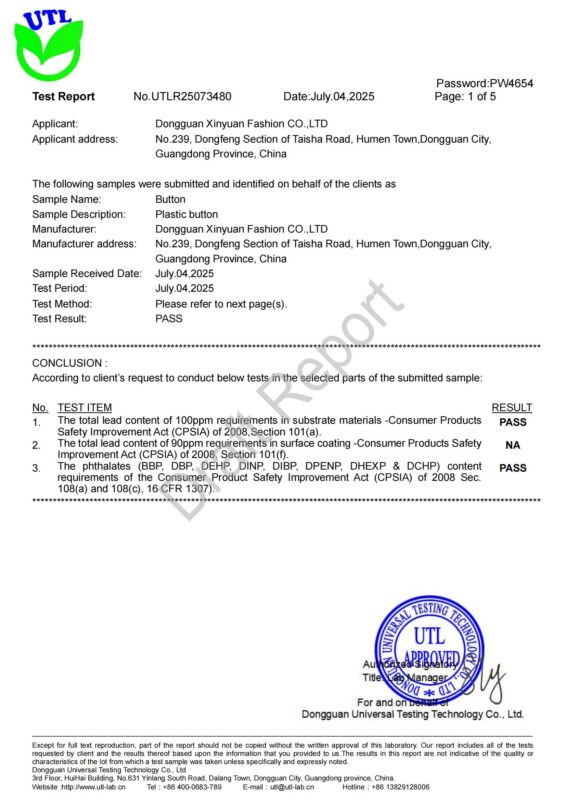

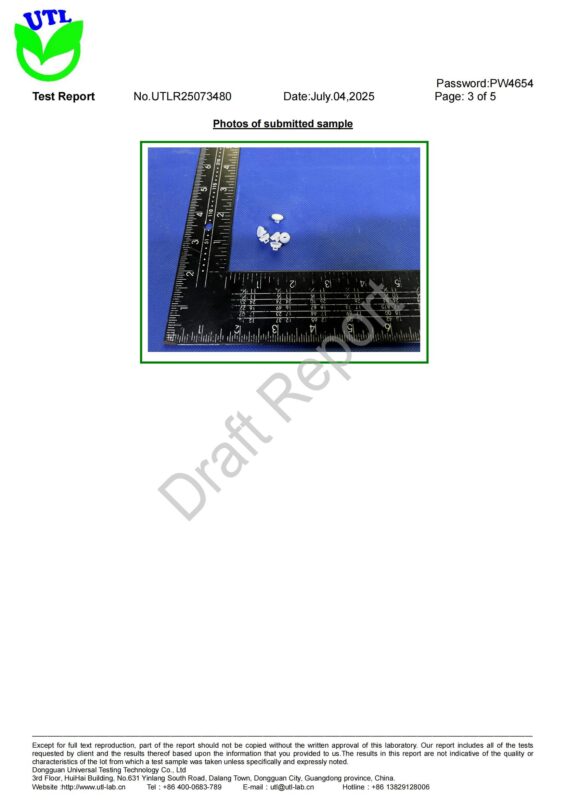

At XINYUAN Apparel, product safety is our top priority. We provide comprehensive CPC certification services ensuring your products meet the Consumer Product Safety Commission (CPSC) standards in the United States. Our testing includes strict screening for hazardous substances such as lead and benzene, fully complying with the Consumer Product Safety Improvement Act (CPSIA) regulations.

Our in-house lab and trusted partners perform accurate lead content testing and benzene testing to guarantee that your garments and accessories are safe for consumers, especially children. With the CPC certificate and CPSIA compliance, your products can confidently enter the US market without safety concerns or regulatory issues.

Key Services Include:

CPC Certificate Issuance

Lead Content Testing (CPSIA Lead Limits)

Benzene Residue Testing

Comprehensive Safety Compliance Reports